Challenging supply chains and workforces have disrupted the global manufacturing and industrial landscape. We are entering an era of unprecedented economic uncertainty, and it’s natural to wonder what lies ahead. Will growth stall and profits decline?

Being slow on trend uptake or failing to keep pace could result in manufacturers struggling against rivals who capitalize more effectively on cutting-edge technologies. Manufacturers must embrace change, invest in research and development, and empower their workforce with new skills to seize opportunities.

This blog delves into the most important trends shaping the manufacturing and industrial sectors in 2023.

Revolutionizing Manufacturing: Key Trends to Watch in 2023

A lot has been happening in the manufacturing industry, and not all trends require attention, but some should not be ignored for attaining growth and expansion. Let’s have a look at the four trends to watch for in 2023.

1. Industry 4.0

As we dive into the year ahead, one topic stands out prominently. Industry 4.0, considered the fourth industrial revolution. It’s a concept centering on innovative technologies such as AI, IoT, and advanced robotics converging to form smarter, more productive factories geared towards optimizing data-driven efficiency. One of the key components driving this revolution forward is the Industrial Internet of Things (IIoT).

IIoT is enabled by secure connections between ‘edge’ devices linked via local networks and advanced cloud storage platforms. Its essential value lies in its capability to provide real-time data supporting informed decision-making on critical operational metrics such as:

-

- Plant-floor optimization timing reduction strategies

-

- Improving process safety standards

-

- Yield enhancements

-

- Seamless connectivity for advanced supply chain management models

Smart manufacturing builds upon the foundations laid by the IoT, aiming to create truly data-driven organizations with hyperflexible, self-adapting capabilities. Thus, moving beyond production-based business strategies toward agility in recognizing evolving consumer needs.

The future is bright for IIoT ecosystems driving enhanced efficiency goals, cost savings measures, and safety advancements culminating in superior product innovation. The implementation of IIoT has already gained significant traction, and its value is projected to soar to $106 billion by 2026, further fueling its expansion in the coming years.

2. Predictive Maintenance

Predictive maintenance will be big in 2023 and the years to come. This pivotal trend, known as predictive resolution, builds upon the foundations of predictive maintenance, revolutionizing how manufacturers address equipment performance issues with unwavering precision and confidence.

For years implementing predictive resolutions has faced challenges linked with the absence of significant historical data sets, which are required in setting up accurate benchmarking systems and models. However, with Artificial Intelligence (AI) taking major strides in terms of its capabilities, manufacturers can now harness Machine Learning and Natural Language Processing (NLP) to analyze data from unstructured data types such as Word documents, Excel sheets, or PDF files.

The application of these technological advancements now enables producers to extract crucial information from seemingly disorganized data sources and make them usable on analytical platforms, thus unlocking new thresholds previously not possible in predictive maintenance.

Predictive maintenance provides a huge step forward for manufacturers, allowing them to improve equipment efficiency, lower costs, and increase first-time fix rates. As predictive resolution’s underlying technology evolves and gets more sophisticated, its adoption becomes more accessible and economical for manufacturers of all sizes.

3. Sustainable Manufacturing

As the world unites in its commitment to attaining Net Zero and combating climate change, the manufacturing industry stands at the forefront of this global movement. One of the primary reasons sustainability has gained traction in the manufacturing industry is the growing realization of the environmental consequences associated with traditional production models.

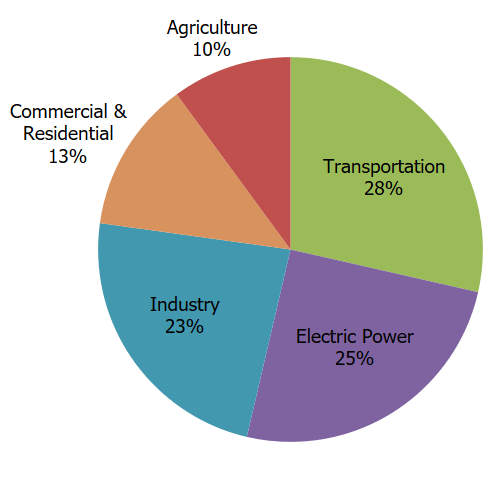

The alarming statistics reveal that U.S. manufacturing alone contributes to 23% of the nation’s direct carbon emissions. Such figures have compelled manufacturers to reassess their operations and seek alternative approaches.

Enter the circular economy, a transformative model that has captured the attention of forward-thinking manufacturers. The circular economy departs from the linear “take-make-waste” mindset and advocates for a more sustainable approach based on the “7 Rs”: rethink, redesign, repurpose, repair, remanufacture, recycle, and recover.

Sustainability in the manufacturing industry goes beyond environmental consciousness. It embodies the responsible and efficient use of resources, ensuring their availability for future generations. Embracing sustainability and circular economy principles offers not only ecological benefits but also economic advantages.

4. Additive Manufacturing with Advanced Materials

Manufacturing is set to witness two powerful forces converge and shape the industry’s future in 2023: additive manufacturing and advanced materials. The combination of these transformative technologies is poised to revolutionize how products are designed, fabricated, and utilized, ushering in a new era of innovation and efficiency.

Additive manufacturing, commonly known as 3D printing, has enabled rapid prototyping leading to accelerated design iterations, which denotes a reduced time to market and simultaneously nurtures continuous innovation. Manufacturing complex components with precision is highly advantageous while producing complicated parts at reduced time frames.

Compared to traditional subtractive manufacturing techniques, such as component manufacturing using milling machines, that require extensive tooling and tend to leave significant waste generation levels, additive manufacturing offers considerable savings overall.

Advances in nanotechnology, biotechnology, and materials science have led to material development with superior physical or chemical properties compared to traditional ones, thus spearheading the adoption of additive manufacturing trends further into 2023.

Additive manufacturing shall provide endless growth opportunities primarily due to the feature-rich nature of these cutting-edge materials.

Summing it Up

As we look ahead to 2023, the manufacturing industry stands on the precipice of transformative change. The trends that will shape the landscape are bold and promising, holding the potential to revolutionize traditional practices and unlock new levels of efficiency, sustainability, and innovation, i.e., smart manufacturing.

As we embark on this journey, let us remember that the manufacturing industry is not just about machines and processes; it is the people behind the innovations, the communities impacted by the products, and the responsibility we bear for the world we inhabit.

Author Bio:

Peter Jacobs

Peter Jacobs is the Senior Director of Marketing at CNC Masters. He is actively involved in manufacturing processes and regularly contributes his insights to various blogs on CNC machining, 3D printing, rapid tooling, injection molding, metal casting, and manufacturing in general.