Looking for the right shipping container to properly store and ship your cargo? You may already be aware that the volume of the shipping container, as well as its dimensions, are key factors when making your selection. But did you know it goes deeper than that?

Choosing the right shipping container for your cargo involves many considerations. You need to evaluate factors like the number of containers required, whether your products are too tall or irregularly shaped, or if they need refrigeration or specialized loading equipment like forklifts. One key aspect is container capacity. For example, while types of containers vary, the standard large containers (40 ft x 8 ft) can hold up to 20 tons.

This guide will cover container dimensions, sizes, and types to ensure efficient cargo calculations for transport.

What Are the Different Types of Shipping Containers?

Sure, some things in life tend to hold more appeal when there is an “air of mystery” about them but not when it comes to shipping containers. Every detail matters – even the small ones. That’s right, size matters. And so does the type and volume of shipping containers.

Let’s begin with detailing the different types of containers available for shipping cargo across countries, so you can pick the one most suitable for your needs:

Standard Dry Shipping Containers

The most common general-purpose containers are versatile and used for shipping by rail, road, or sea. These containers, typically for dry solid products, are designed to prevent moisture intrusion. They are generally 8 feet (2.43m) wide and 8.5 feet (2.59m) high and come in 20-ft and 40-ft lengths. Made of either steel or aluminum, steel containers offer a slightly larger internal capacity, while aluminum containers provide a higher payload capacity and are frequently used for domestic shipping. More rare is the 45-ft container length which can be more difficult to find a chassis for and is generally not recommended for most freight.

Open-Top Containers

If your products are too large for standard containers but don’t require a high cube unit and need forklift access, open-top containers offer a practical solution. They are specifically designed with a removable top to make loading and unloading easier. Despite the name, these containers aren’t left uncovered during shipping. Instead, they are equipped with either a removable steel roof or a tarpaulin cover to protect the cargo while in transit, ensuring your goods stay secure and shielded from the elements.

Flexitank Containers

What if you need to transport large quantities of non-hazardous liquids like water or cooking oil? Flexitank containers are designed specifically for this purpose. These containers feature a collapsible, hermetically sealed bag that holds the liquid securely inside the container, preventing movement during transport. Typically, a flexitank can carry between 10,000 and 24,000 liters of liquid but can be customized to handle up to 100,000 liters depending on your needs. This makes them an efficient and adaptable solution for bulk liquid transportation.

High Cube Containers

A high cube container is approximately a foot taller than standard dry containers making it perfect for products that need extra height or space. These are well-suited for short-sea shipping and have the same loading capacity as trailers. High cube variations come in both 20-ft and 40-ft containers.

Insulated Containers

When shipping temperature-sensitive products like pharmaceuticals, frozen foods, fresh produce, or chemicals, insulated or thermal containers are essential. These containers maintain a stable internal climate to ensure the safe transport of items that must be kept at specific temperatures. They are fitted with a mechanical compressor that regulates the temperature, similar to how a thermos works, keeping the cargo either cool or warm throughout the journey. This ensures protection from contamination and preserves product integrity during long-distance hauls.

Refrigerated Containers

Refrigerated or reefer containers are used for shipments that need temperature control. These are equipped with a refrigeration unit connected to the power supply on a ship. Refrigerated containers maintain a certain temperature, ventilation, and humidity to efficiently ship temperature-sensitive goods like fruits, meat, vegetables, seafood, or dairy.

Determining the Volume of Shipping Container

It’s a general rule of thumb to properly calculate the size and weight of your cargo, before shipping. Why is this important?

A container load, or the maximum amount of cargo that can be loaded into a shipping container, is determined by the size and weight of the cargo and is usually calculated based on a standard 20-ft or 40-ft shipping container.

The size and weight of the cargo will determine how many items can fit comfortably in a container load. Container loads are typically used when shipping large quantities of products at once. This offers cost savings over less efficient methods such as loose freight and bulk shipping. In overseas manufacturing, it is important to understand how much product can fit in one container so you can pack it efficiently.

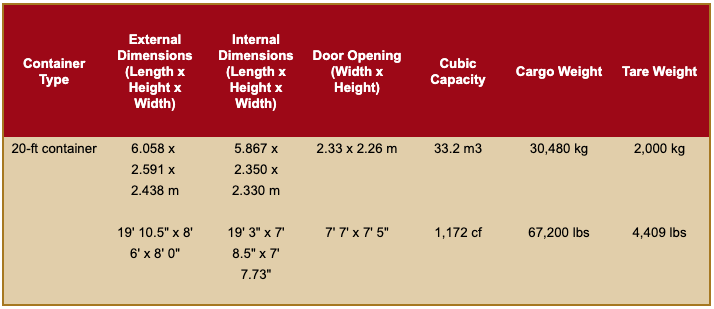

20-ft Standard Container Dimensions

A 20-ft container is roughly the size of a car garage. These are easy to stack on vessels, making them relatively inexpensive to ship.

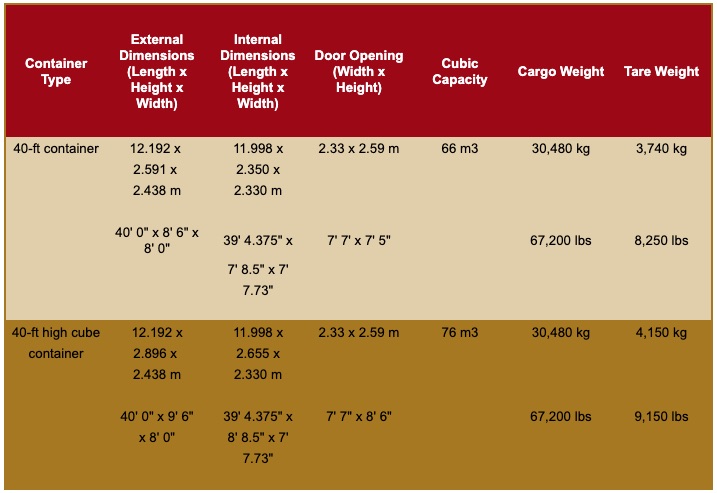

40-ft Standard Container Dimensions

Compared to 20 ft containers which are primarily used to ship heavy machinery, 40 ft containers are commonly used for larger amounts of consumer goods like clothing, electronics, cars, or furniture. A high cube 40 feet container is used for over-height goods; these can be up to 2.7 meters or 8.1 feet tall.

How to Calculate Shipping Container Capacity

To estimate your container load by hand, you’ll need to follow these steps:

Measure the internal container dimensions– the inside length, width and height of the shipping container. For instance, the inside of a 20-foot-long container usually measures 19 feet, 4 inches long, 7 feet 9 inches wide, and 7 feet 10 inches high.

Multiply the length, width and height of your container to determine the volume available for your items. For instance, from our dimensions above, a 20-foot container would offer approximately 1,173 cubic feet.

Measure each individual box, bin, pallet or crate to determine the volume of each shipping unit.

Divide 90 percent of the total shipping volume of the shipping container by the volume of the shipping unit to estimate the number of boxes, bins, pallets or crates that will fit inside your container.

Reduce the loading quantity further, as needed, to meet mandated highway transport weight restrictions at the delivery destination.

Expect that carton size and shape as well as loading configuration and orientation can further limit container loading capacity.

When planning the loading of your shipping container, you’ll need to fully understand what’s in each box and the limitations of the packing materials. Similar items can be grouped together, while some items can be stacked on top of one another. Fragile items, of course, should not be stacked.

You may also need to consider using dunnage (also known as padding) that will be placed between cargo items to prevent damage. When using dunnage, be sure to wrap your item ahead of time and then measure the volume of each item. This ensures that you correctly calculate exactly how many items will fit in the shipping container’s capacity.

When importing items from overseas, it’s also important to load items in a way that’s easy for customs inspectors to inspect. Shipping containers are most commonly either floor-loaded with cartons or pallet-loaded. Be mindful of weight distribution within the container, as it could make it unsafe. You’ll also increase your chances of avoiding any exam holds from customs officials who typically examine containers that have been improperly or unprofessionally loaded.

NOTE: Need a useful tool for planning and calculating container space for shipping overseas? Visit our website to use ITI’s FREE cargo load calculator. With just a few clicks, you can quickly determine:

- The number of cartons or pallets you can fit in one shipping container.

- The best way to maximize space in a container during loading.

- How to arrange complex loading for multiple SKUs.

- Number of containers needed per shipment.

Need Help Calculating Shipping Container Dimensions?

When partnering with ITI, optimizing the volume of shipping containers is handled for you by our in-house experts. We also provide HTS code designation, ocean freight booking, weekly updates of shipment status to ensure delivery satisfaction, ocean freight and rail transit monitoring, U.S. Customs clearance, and all duties and tariffs paid. Further, we will even arrange local trucking where needed.

Contact us today if you would like more detailed assistance with production and shipment.