Ever wonder why so much of the technology in your pocket traces back to one city in China? Known as the Silicon Valley of China, Shenzhen has grown from a small fishing village into one of the most advanced manufacturing hubs.

That kind of speed and scale didn’t happen overnight. Shenzhen became one of China’s first special economic zones (SEZs) in the 1980s, attracting investment and quickly becoming a hub for factories, suppliers, and skilled labor. Over time, it developed the infrastructure and know-how that make it the center of global electronics and hardware production today.

Why Shenzhen Is Called the Silicon Valley of China

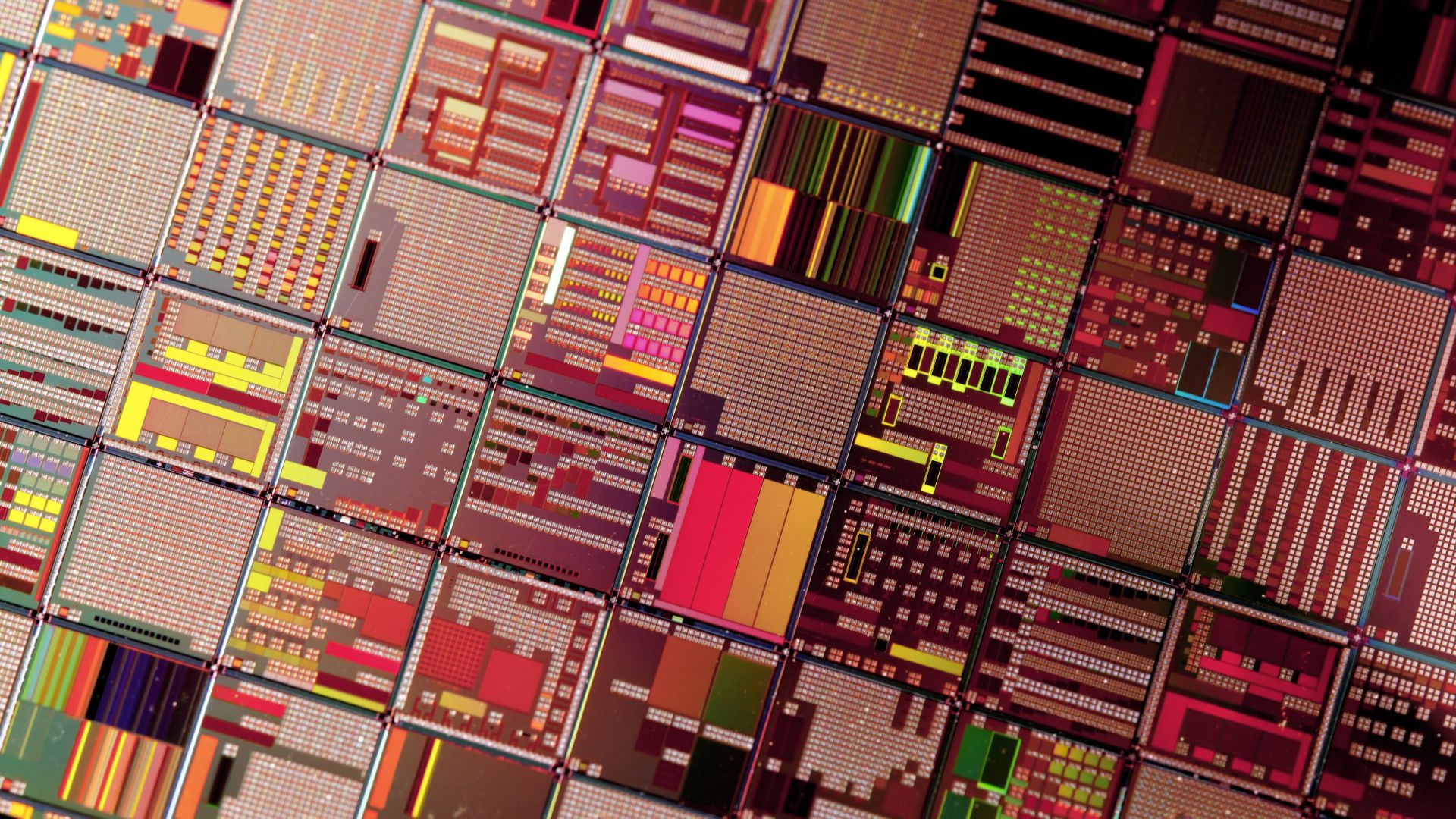

Shenzhen earned its reputation as the Silicon Valley of China for good reason. The city is packed with factories and engineers, supported by a vast range of component suppliers and logistics providers. Together, they form one of the most concentrated hardware ecosystems in the world.

Companies can design and prototype in Shenzhen, then move into mass production and testing without leaving the region. That efficiency saves time, reduces costs, improves quality, and accelerates time-to-market.

The scale is staggering. In the first seven months of 2025, Shenzhen’s foreign trade reached about $361 billion, ranking it first among Chinese cities for trade volume. Nearly three-quarters of that came from electromechanical products, which include smartphones, printed circuit boards, and integrated circuits.

Today, those exports continue to climb. Integrated circuits alone rose by more than 40 percent year over year. These numbers highlight why global companies still see Shenzhen as the heartbeat of the China electronics supply chain.

The city is also home to household names like Huawei, as well as the supplier base behind major U.S. brands such as Apple and General Motors. Add government policies that prioritize exports and innovation, and the path behind Shenzhen’s success becomes clear.

What Makes Shenzhen Unique for U.S. Companies

For U.S. manufacturers, Shenzhen offers something rare: an entire supply chain ecosystem contained in one region. Need a prototype of a circuit board and an injection-molded casing? Those resources are within reach, along with assembly lines and packaging facilities ready to finish the job. This level of density means companies can go from concept to production faster than almost anywhere else.

The workforce adds another advantage. Shenzhen has built a large pool of employees trained in electronics and robotics, with specialties ranging from IoT to advanced automation. That breadth of expertise gives companies confidence that their products can scale without losing quality.

Logistics strengthen the equation. Shenzhen sits on the Pearl River Delta and neighbors Hong Kong, with major ports, rail hubs, air freight capacity, and road networks linking directly to export markets. For companies balancing tight schedules and cost pressures, Shenzhen is an attractive option for electronics production in China.

Infrastructure like that helps, but navigating it successfully takes more than access alone. At ITI Manufacturing, we take the stress out of managing suppliers across time zones. Our teams handle overseas manufacturing directly, so our clients gain speed and scale while we handle the details.

Challenges of Manufacturing in Shenzhen (Without a Local Partner)

Shenzhen may be the Silicon Valley of China, but success isn’t guaranteed. Companies entering this environment without a trusted partner often face challenges that quickly derail projects.

Language and cultural differences can turn precise specifications into costly mistakes. Intellectual property protection is another concern. Without proper contracts and oversight, designs can be copied or misused. Supplier quality varies widely, and the city’s fast pace means small errors can multiply into a shipment of defective parts before you realize what happened.

Tariffs and trade compliance add another layer of complexity. The U.S.-China trade relationship keeps shifting, and mistakes in labeling or paperwork can hold shipments at customs.

This is where ITI makes a difference. Our account managers in the U.S. handle pricing and strategy, while our in-country staff in China verify quality, enforce contracts, communicate with suppliers, and monitor production on-site. With vetted factories and established processes, ITI helps clients navigate the realities of contract manufacturing in China without unnecessary risk.

When Shenzhen Manufacturing Makes Sense

Not every project belongs in Shenzhen, but many do. High-volume consumer electronics are a natural fit, since the city’s infrastructure was built to support them. Companies with prototypes that need to scale quickly also benefit, since Shenzhen’s supplier clusters are optimized for rapid iteration.

Complex products that rely on multiple suppliers for different parts of the bill of materials are another strong candidate. The ability to coordinate components, assemblies, packaging, and logistics within a single region saves time and money. And for time-sensitive projects where time-to-market is critical, Shenzhen often delivers when other areas can’t.

Deciding whether a project belongs in Shenzhen requires careful evaluation and research. That’s why ITI Manufacturing evaluates each customer’s needs to determine if tech manufacturing in Shenzhen is the right move. When it is, we provide oversight and experience to ensure feasibility and cost-effectiveness at every stage.

Shenzhen Is the Silicon Valley of China (But You Still Need a Guide)

Shenzhen’s reputation as the Silicon Valley of China is well-earned. No other city offers such a powerful mix of supply chain density, skilled labor, infrastructure, and global logistics. The statistics prove it.

With hundreds of billions of dollars in trade and explosive growth in high-tech exports, Shenzhen continues to set the pace for global manufacturing. This kind of scale creates unmatched opportunities, but it also brings risks if you go it alone.

At ITI, our staff in China verifies quality, oversees production, and communicates directly with suppliers, while our U.S. account managers set strategy and timelines. This dual presence keeps projects on track, protects intellectual property, and ensures smoother customs clearance. With our vetted network of suppliers across plastics, metal, and custom component parts, we connect U.S. companies to Shenzhen’s strengths without the guesswork.

Interested in production in China and ready to explore Shenzhen’s potential?Speak with one of our experts today and move your product from idea to delivery with confidence and control.